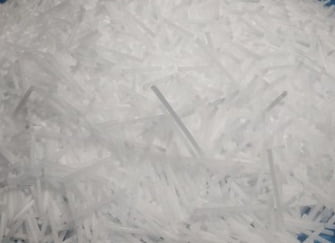

Mashine ya Shuliy ya pellets za barafu kavu imeundwa kubadilisha kaboni dioksidi ya kioevu (CO2) kuwa vipande vya barafu kavu vyenye ukubwa wa Φ3-19mm. Inaweza kuzalisha 50-500kg/h ya pellets za barafu kavu.

Chembechembe hizi za barafu kavu zinaweza kutumika katika kutoa athari za moshi, uhifadhi wa chakula, usafirishaji wa mnyororo baridi, kusafisha barafu kavu, nk.

Mashine yetu ya punjepunje ya barafu kavu ina muundo wa kompakt, matokeo ya juu na bei nzuri. Inaweza kutimiza hitaji lako la kutoa pellets kavu za barafu za hali ya juu.

Ikiwa una nia, karibu kuwasiliana nasi kwa maelezo zaidi ya mashine!

Faida za mashine ya pellet ya barafu kavu

- Mashine hii ina pato la 50-500kg/h. Inaweza kutoa 50-500kg/h ya pellets kavu za barafu kwa kutumia kioevu CO2.

- Shuliy mashine inaweza kuzalisha pellets kavu barafu kutumika katika minyororo baridi, kusafisha viwanda, hatua, maabara, nk.

- Mfumo wa udhibiti wa mashine huchukua hali ya juu PLC na uendeshaji kamili wa skrini ya kugusa ili kutambua zaidi otomatiki wa mashine.

- Mashine yetu ni iliyotengenezwa kwa chuma cha pua, maisha ya kudumu na ya muda mrefu ya huduma.

- Tunaweza Customize mwonekano wa mashine, saizi kavu ya pellet ya barafu, voltage ya mashine, nguvu, nk.

Vigezo vya kiufundi vya mtengenezaji wa pellet ya barafu kavu

| Mfano | SL-50 | SL-100 | SL-150 | SL-200 | SL-300 | SL-400 | SL-500 |

| Uwezo (kg/h) | 50 | 100 | 150 | 200 | 300 | 400-450 | 500 |

| Vipimo vya pellet kavu ya barafu(mm) | Φ3-Φ16 | Φ3-Φ19 | Φ3-Φ19 | Φ3-Φ19 | Φ3-Φ19 | Φ3-Φ19 | Φ3-Φ19 |

| Uzito wa barafu kavu (kg/m³) | 1550 | 1550 | 1550 | 1550 | 1550 | 1550 | 1550 |

| Uwiano wa ubadilishaji | ≥42% | ≥42% | ≥42% | ≥42% | ≥42% | ≥42% | ≥42% |

| Nguvu (k) | 3 | 4 | 7.5 | 5.5 | 7.5 | 15.5 | 18.5 |

| Uzito(kg) | 200 | 350 | 600 | 650 | 1200 | 1900 | 2500 |

| Vipimo(cm) | 100×50×100 | 128×60×140 | 135×65×165 | 148×100×151 | 135×120×158 | 165×135×168 | 165×145×175 |

Kama unaweza kuona kutoka kwa jedwali hapo juu, tuna aina nyingi za mifano ya mashine ya pellet ya barafu iliyo na anuwai ya pato. Mbali na hili, unaweza kujua ukubwa wa pellets kavu ya barafu, kiwango cha ubadilishaji, uzito wa mashine, vipimo, nk Hizi zinaweza kukusaidia wakati wa kuchagua mashine.

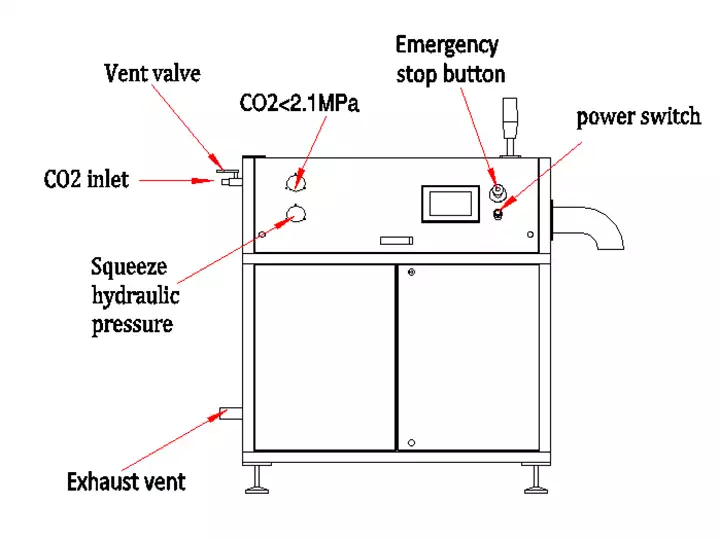

Muundo wa pelletizer ya barafu kavu

Mashine yetu ya pellet ya barafu kavu ina njia ya kuingilia (kuunganisha na tanki ya kioevu ya CO2), skrini ya kugusa ya PLC, kipimo cha shinikizo, swichi ya nguvu, kitufe cha kusimamisha dharura, kituo, n.k.

Kanuni ya kazi ya mashine kavu ya pellet ya barafu

Kitengeneza pellet ya barafu kavu hutumia halijoto ya chini kufinya kioevu cha CO₂ kinachozunguka kwa kasi ya juu hadi kwenye pellets ngumu kwenye chumba cha kutengeneza barafu. Pellets kavu za barafu za ukubwa na urefu fulani hutolewa kupitia sahani ya ukungu ndani ya mashine. Hatimaye, unaweza kuweka chombo kavu cha kuhifadhi barafu kwenye bandari ya kutoa ili kukusanya pellets kavu za barafu.

Maombi ya pellets kavu ya barafu

Mashine ya kukausha barafu ni maarufu sokoni kwa sababu pellets kavu za barafu zina matumizi yafuatayo.

- Kwa chakula cha friji. Kwa sababu barafu kavu ni kipozezi kizuri, inaweza kutengeneza mazingira ya halijoto ya chini wakati wa kuhifadhi chakula. Hii inafaa kwa uhifadhi wa chakula.

- Inatumika katika shamba la uzalishaji wa chakula na vinywaji. Barafu kavu mara nyingi huongezwa kwenye ice cream na vinywaji kama "kiungo", ambayo ni baridi wakati wa kunywa. Pia inaboresha sana ladha ya vinywaji.

- Kufanya athari za hatua. Barafu kavu inaweza kuyeyushwa moja kwa moja kuwa gesi ya halijoto ya chini na kaboni dioksidi kavu, na inaweza kuunda athari ya wingu pepe. Kwa hivyo, mara nyingi hutumiwa kwa maonyesho ya jukwaa.

- Inatumika kwa kusafisha viwanda. Kwa sababu ya uvukizi wake rahisi, barafu kavu inaweza kutumika kusafisha uchafu kwenye sehemu za ndani za vifaa vya viwandani bila uharibifu wake.

Je, ni wateja gani wawezao kuwa wateja wa mashine ya kukausha barafu?

Mara tu unapojua ni pellets za barafu kavu hutumiwa, basi ni nani anayenunua?

Vitengeneza barafu kavu vya CO2 vimetumika mara nyingi katika:

- Mikahawa

- Hoteli

- Maduka makubwa

- Masoko ya vyakula vya baharini

- Viwanda vya usindikaji wa maji

Vifaa vinavyolingana

Katika hali tofauti, mashine ya kukausha barafu inaweza kutumika pamoja na vifaa tofauti.

- Kwa utengenezaji wa pellet kavu ya barafu, inaweza kufanya kazi na tanki ya Dewar (tangi ya CO2 ya kioevu).

- Kwa ulipuaji wa viwandani, inafanya kazi kila wakati na mashine kavu ya kusafisha barafu.

- Kwa briquetting kavu ya barafu, hutumiwa na mashine kavu ya briquette ya barafu.

Vipi kuhusu bei ya mashine kavu ya pellet ya barafu?

Bei za mashine ya barafu kavu hutofautiana kulingana na mfano, uwezo wa uzalishaji na vipengele vya ziada.

- Mashine ndogo za barafu kavu kwa kawaida ni nafuu zaidi na zinafaa kwa biashara ndogo hadi za kati.

- Watengenezaji wa barafu kavu kubwa na wenye uzalishaji wa juu ni ghali zaidi na wanafaa kwa mahitaji ya uzalishaji wa wingi wa viwanda.

Uchaguzi unahitaji kuzingatiwa kulingana na maombi maalum na bajeti. Ikiwa unataka maelezo zaidi, tafadhali jisikie huru kuwasiliana nasi kwa habari zaidi!

Fanya mpango uliofanikiwa na mtengenezaji wa pellet ya barafu ya Shuliy

Ikiwa unataka kufanikiwa kununua mashine yetu ya barafu kavu, mchakato ufuatao ni wa kumbukumbu yako:

- Kuwasiliana na mahitaji yako

- Ushauri wa bidhaa

- Mpango uliobinafsishwa

- Kusaini mkataba

- Malipo ya amana

- Uzalishaji na upimaji

- Usafirishaji

- Huduma ya baada ya mauzo

Video inayofanya kazi ya pelletizer ya kioevu ya CO2

Maswali Yanayoulizwa Mara kwa Mara

Ninaweza kununua wapi kaboni dioksidi kioevu?

Kwa ujumla, unaweza kuinunua kutoka kwa mmea wa kemikali. Bei ni tofauti katika mikoa na misimu tofauti.

Ni mara ngapi kipulizia kavu cha barafu kinadumishwa?

Angalia mashine mara moja kila baada ya miezi 3.

Je, ni gharama gani za matumizi ya kila mwaka ya mashine ya kukausha barafu?

Inajumuisha gharama ya mafuta ya majimaji, matumizi ya nguvu, matumizi ya kioevu ya CO2 na gharama ya kazi.

Mafuta ya majimaji yanahitaji kubadilishwa mara moja kwa mwaka.

Je, urefu wa chembe za barafu kavu ni ngapi?

Fracture ya asili, hivyo urefu haujawekwa.

Je! barafu kavu inaweza kuhifadhiwa kwa muda gani?

Inaweza kuhifadhiwa kwenye sanduku kavu la barafu kwa zaidi ya wiki.

Je, ni kiwango gani cha kubadilika kwa barafu kavu?

3-6% katika 24h.

Ni shinikizo gani la mafuta linalofanya kazi la mashine kavu ya punjepunje ya barafu?

Shinikizo la juu la mafuta ni 21MPa.

Je, hewa iliyobanwa itatumiwa?

Hewa iliyobanwa haihitaji kutumiwa ikiwa uwezo wa uzalishaji wa barafu kavu ni chini ya 600kg/h.

Je, ni gharama gani ya uendeshaji wa mtengenezaji wa pellet kavu ya barafu?

Kwa ujumla, huhesabiwa kama mara 3 za CO2 ya kioevu ya malighafi.

Tangi la kuhifadhia CO2 linahitajika kwa ukubwa wa 200kg/h kwa mashine ya kusambaza barafu kavu?

Zaidi ya mita 5 za ujazo.

Je, ninaweza kubadilisha nguvu kuwa injini ya dizeli?

Injini ya dizeli haipendekezi. Jenereta ya dizeli inapendekezwa.

Ni nini nguvu na uwezo wa kitengo cha kurejesha gesi ya kaboni dioksidi mkia?

500kg/h nguvu 140kW, 1000kg/h nguvu 270kw.

Je, vikataji vinaweza kuongezwa kwenye kipulizia kavu cha barafu?

Inaweza kuwa na vifaa vya kukata kwenye duka ili kukata chembe.

Je, sanduku la kuhifadhi barafu kavu linaweza kufanywa kuwa nyeusi?

Idadi ya zaidi ya 100 inaweza kubinafsishwa, na nembo inaweza kubinafsishwa.

Je, ninaweza kuongeza chembe za barafu kavu kwenye vinywaji?

Ndiyo.