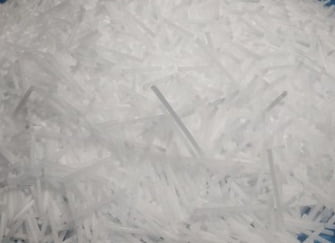

Shuliy dry ice pellet machine is designed to transform liquid carbon dioxide(CO2) into dry ice pellets with sizes of Φ3-19mm. It can produce 50-500kg/h of dry ice pellets.

These dry ice granules can used in producing smoke effects, food preservation, cold chain transportation, dry ice cleaning, etc.

Our dry ice granular machine has a compact structure, high outputs and a favorable price. It can fulfill your need to produce high-quality dry ice pellets.

If you’re interested, welcome to contact us for more machine details!

Advantages of dry ice pellet machine

- This machine has an output of 50-500kg/h. It can produce 50-500kg/h of dry ice pellets using liquid CO2.

- Shuliy machine can produce dry ice pellets used in cold chains, industrial cleaning, stage, laboratory, etc.

- The machine control system adopts high-end PLC and full touchscreen operation to further realize machine automation.

- Our machine is made of stainless steel, dural and long service life.

- We can customize machine appearance, dry ice pellet size, machine voltage, power, etc.

Technical parameters of dry ice pellet maker

| Model | SL-50 | SL-100 | SL-150 | SL-200 | SL-300 | SL-400 | SL-500 |

| Capacity(kg/h) | 50 | 100 | 150 | 200 | 300 | 400-450 | 500 |

| Dry ice pellet specifications(mm) | Φ3-Φ16 | Φ3-Φ19 | Φ3-Φ19 | Φ3-Φ19 | Φ3-Φ19 | Φ3-Φ19 | Φ3-Φ19 |

| Dry ice density(kg/m³) | 1550 | 1550 | 1550 | 1550 | 1550 | 1550 | 1550 |

| Conversion ratio | ≥42% | ≥42% | ≥42% | ≥42% | ≥42% | ≥42% | ≥42% |

| Power(kw) | 3 | 4 | 7.5 | 5.5 | 7.5 | 15.5 | 18.5 |

| Weight(kg) | 200 | 350 | 600 | 650 | 1200 | 1900 | 2500 |

| Dimensions(cm) | 100×50×100 | 128×60×140 | 135×65×165 | 148×100×151 | 135×120×158 | 165×135×168 | 165×145×175 |

As you can see from the table above, we have a wide variety of dry ice pellet machine models with a wide range of output. In addition to this, you can know the sizes of dry ice pellets, conversion rate, machine weight, dimensions, etc. These can help you when choosing a machine.

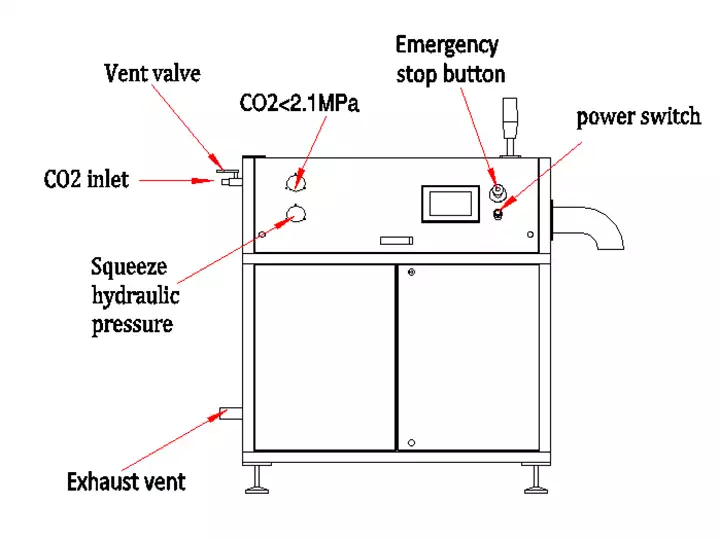

Structure of dry ice pelletizer

Our dry ice pellet machine has inlet(to connect with liquid CO2 tank), PLC touchscreen, pressure gauge, power switch, emergency stop button, outlet, etc.

Working principle of dry ice pellet machine

The dry ice pellet maker uses the low temperature to condense the liquid CO₂ rotating at high speed into solid pellets in the ice-making chamber. Dry ice pellets of a certain size and length are then extruded through a mold plate inside the machine. Finally, you can put a dry ice storage container at the discharging port to collect the dry ice pellets.

Applications of dry ice pellets

The dry ice pellet machine is popular in the market because the dry ice pellets have the following applications.

- To refrigerate food. Because dry ice is a good coolant, it can form a lower-temperature environment when storing food. This is conducive to food storage.

- Used in the food and beverage production field. Dry ice is often added to ice cream and drinks as an “ingredient”, which is cool when drinking. It also greatly improves the taste of drinks.

- To make stage effects. Dry ice can be directly evaporated into low-temperature and dry carbon dioxide gas, and it can form a virtual cloud effect. Thus, it’s often used for stage performances.

- Used for industrial cleaning. Because of its easy evaporation, the dry ice can be used for cleaning the dirt on the inner parts of industrial equipment without damage to it.

Who are potential dry ice pellet machine customers?

Once you know what dry ice pellets are used for, then who buys them?

CO2 dry ice makers have been often used in:

- Restaurants

- Hotels

- Supermarkets

- Seafood markets

- Aquatic processing factories

Matched equipment

In different situations, a dry ice pelletizer machine can be used together with different equipment.

- For dry ice pellet making, it can work with the Dewar tank (liquid CO2 tank).

- For industrial blasting, it always works with the dry ice cleaning machine.

- For dry ice block briquetting, it’s used with the dry ice pellet briquette machine.

How about the price of dry ice pellet machine?

Dry ice machine prices vary depending on the model, production capacity and additional features.

- Smaller dry ice machines are usually more affordable and suitable for small to medium-sized businesses.

- Larger, high-production dry ice makers are more expensive and suitable for industrial mass production needs.

The choice needs to be considered based on the specific application and budget. If you want more details, please feel free to contact us for more information!

Make a successful deal with Shuliy dry ice pellet maker

If you want to successfully purchase our dry ice machine, the following process is for your reference:

- Communicating your needs

- Product consulting

- Customized plan

- Contract signing

- Deposit payment

- Production and testing

- Shipping

- After-sales service

Working video of liquid CO2 pelletizer

FAQ

Where can I buy liquid carbon dioxide?

Generally, you can buy it from a chemical plant. The prices are different in different regions and seasons.

How often is the dry ice pelletizer maintained?

Check the machine once every 3 months.

What are the annual use costs of the dry ice pellet machine?

It includes the cost of the hydraulic oil, the power consumption, liquid CO2 consumption and labor cost.

The hydraulic oil needs to be replaced once a year.

What is the length of the dry ice particles?

Natural fracture, so the length is not fixed.

How long can the dry ice be kept?

It can be stored in a dry ice box for more than a week.

What is the volatilization rate of dry ice?

3-6% in 24h.

What is the working oil pressure of a dry ice granular machine?

The maximum oil pressure is 21MPa.

Will compressed air be consumed?

Compressed air does not need to be consumed if the dry ice production capacity is less than 600kg/h.

What is the operating cost of a dry ice pellet maker?

Generally, it is calculated as 3 times of liquid CO2 of raw materials.

How large is a CO2 storage tank needed for the 200kg/h dry ice pellet machine?

More than 5 cubic meters.

Can I change the power to a diesel engine?

Diesel engine is not recommended. A diesel generator is recommended.

What is the power and capacity of the carbon dioxide tail gas recovery unit?

500kg/h power 140kW, 1000kg/h power 270kw.

Can cutters be added to the dry ice pelletizer?

It can be equipped with a cutter at the outlet to cut the particles.

Can the dry ice storage box be made black?

A quantity of more than 100 can be customized, and the logo can be customized.

Can I add dry ice particles to drinks?

Yes.