A máquina de gelo seco em bloco converte principalmente dióxido de carbono líquido em cubos sólidos sob baixas temperaturas e alta pressão. Os cubos de gelo seco podem ser usados em muitos campos, como transporte em cadeia de frio, conservação de alimentos, refrigeração de laboratório e fabricação de efeitos especiais.

Este tipo de máquina de gelo seco tem capacidade de 100-260kg/h. Pode produzir cubos de gelo seco com peso de 0,5-1,2 kg por bloco.

A prensa de bloco de gelo seco Shuliy tem a vantagem de refrigeração rápida, baixo consumo de energia e fácil operação, muito adequada para pequenas e médias empresas e laboratórios. Se estiver interessado, entre em contato conosco para mais detalhes!

Vantagens da máquina de bloco de gelo seco

- A máquina de gelo seco Shuliy tem um capacidade de 100-260kg/h, e pode produzir blocos de gelo seco com um peso de 0,5-1,2 kg.

- A máquina pode produzir cubos de gelo seco com espessura ajustável (15-70mm).

- É feito de aço inoxidável 304, longa vida útil.

- Esta máquina pode transformar dióxido de carbono líquido em tijolos de gelo seco com um proporção de

≥43,5%. - Você pode operar a máquina somente através do Tela sensível ao toque do CLP na máquina, o que é muito simples e seguro.

- Pudermos personalize a tensão da máquina, potência, etc.

Especificações técnicas da máquina para fazer blocos de gelo seco

| Modelo | SL-120 | SL-240 |

| Capacidade (kg/h) | 100-160 | 200-260 |

| Tamanho do bloco de gelo seco (L*W*H)(mm) | 125*105*(15-70) | 125*105*(18-70) |

| Densidade de gelo seco (kg/m³) | 1550 | 1450-1550 |

| Taxa de conversão | ≥43,5% | ≥43,5% |

| Potência (kw) | 4 | 8 |

| Peso (kg) | 320 | 800 |

| Dimensão (cm) | 125×60×128 | 142×120×148 |

Nosso fabricante de gelo seco em bloco mais vendido é o SL-120. Além disso, você pode saber o tamanho do bloco de gelo seco, densidade, potência da máquina, peso, etc. Esses dados podem fornecer uma referência quando você escolhe uma máquina de cubos de gelo seco.

Além disso, você pode aprender sobre os dados da máquina de gelo seco SL-240. Se quiser saber mais informações, entre em contato conosco agora!

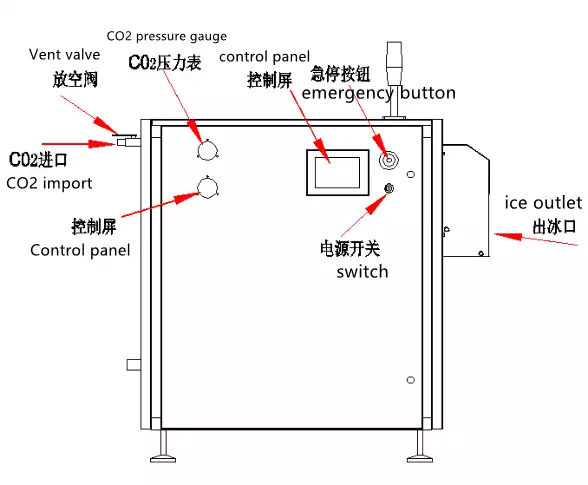

Estrutura do fabricante de blocos de gelo seco

Esta máquina consiste principalmente em entrada de CO2, manômetro, painel de controle, botão de emergência, interruptor, saída de gelo seco, etc.

Como produzir cubos de gelo seco?

A máquina para fazer blocos de gelo seco Shuliy utiliza baixa temperatura e alta pressão para fazer cubos de gelo seco.

- Coleta e compressão de gás dióxido de carbono

- Primeiro, a máquina de bloco de gelo seco introduz dióxido de carbono líquido de um tanque de armazenamento em alta pressão no sistema de compressão da máquina. Aqui, o dióxido de carbono líquido é descomprimido e rapidamente convertido em neve gelada seca.

- Moldagem por compressão de neve de gelo seco

- Em seguida, a neve gelada entra no molde de compressão da máquina. Por meio de um poderoso sistema hidráulico, a neve de gelo seco é comprimida sob alta pressão em densos cubos de gelo seco.

- A pressão de compressão e o tempo deste processo são gerenciados com precisão pelo sistema de controle da máquina. Isso garante que a densidade e o tamanho dos cubos de gelo seco atendam aos requisitos.

- Empurrando e cortando cubos de gelo seco

- Após a conclusão da moldagem por compressão, o molde de compressão se abre e os cubos de gelo seco são expelidos. Conforme necessário, os blocos de gelo seco podem ser cortados em tamanhos específicos para transporte e uso.

- Ciclo automático e produção

- Esta máquina é capaz de produzir cubos de gelo seco continuamente, repetindo automaticamente o processo acima após o final de um ciclo de produção.

- Você pode definir os parâmetros de produção através do painel de controle para realizar a produção em massa.

Funcionamento correto da máquina de gelo seco

- Primeiro, opere manualmente. Pressione primeiro, depois pressione off e então o relé de pressão começa a funcionar.

- Em seguida, o cilindro mestre é comprimido para frente e de volta para o fundo para alimentação por 5 segundos.

- Pressione o botão avançar para comprimir por 3-5 segundos.

- Desligue e esfrie a caixa de compressão por 10 minutos. Empurre os cubos de gelo seco.

- Retraia o cilindro principal para baixo e abra totalmente o cilindro auxiliar. Escolha a operação automática, a produção de gelo seco é normal.

Se quiser saber mais, por favor leia: como usar corretamente a máquina de gelo seco em bloco SL-120?

Qual é o preço da prensa de bloco de gelo seco?

O preço de uma máquina para fazer blocos de gelo seco é afetado pela capacidade da máquina, marca da máquina, serviço pós-venda, etc. Normalmente, máquinas de maior capacidade são relativamente mais caras.

Se quiser saber o preço exato da máquina, não hesite em contactar-nos! Forneceremos a você uma máquina econômica de acordo com suas necessidades.

Dicas para escolher a máquina de fazer blocos de gelo seco adequada

Que tal garantir a compra do equipamento mais adequado para obter os melhores resultados de produção? Com base em nossa experiência, considere o seguinte ao escolher uma prensa de blocos de gelo seco:

- Determinar as necessidades de produção

- Considere a configuração da máquina

- Marca e serviço pós-venda

- Preço e orçamento

Contate-nos agora para máquinas de gelo seco!

Como fabricante e fornecedor profissional de máquinas de produção de gelo seco, temos máquinas de gelo seco em pastilhas, máquinas de gelo seco em bloco, máquinas de jateamento de gelo seco, caixas de gelo seco, etc.

As nossas máquinas podem ajudá-lo a fazer gelo seco com altos lucros. Se quiser saber mais sobre as máquinas de gelo seco Shuliy, entre em contacto connosco a qualquer momento. Forneceremos a melhor solução para satisfazer as suas necessidades!