The dry ice block machine mainly converts liquid carbon dioxide into solid state under the function of huge pressure. This machine mainly uses the pressure generated by hydraulic oil as the motive force. The hydraulic system consists of a frame, a fuel tank, a hydraulic manifold, a cylinder, an electric motor, an oil pump, a solenoid valve, etc. The block dry ice is a liquid that is condensed into a colorless gas at normal temperature and a pressure of 6079.8 kPa and then evaporates rapidly at a low temperature to form a solid substance that is condensed into ice and snow. After the mold of the dry ice block machine is pressed out, it becomes a block of dry ice.

Operation of the dry ice machine:

- First, manually operate, press open, and then press close, and then the pressure relay starts to work.

- Then the master cylinder is compressed forward and back to the bottom for feed 5 seconds.

- Press the push forward button to compress for 3-5 seconds.

- Shut down and cool the compression box for 10 minutes, open the door and push out the dry ice.

- Retreat the master cylinder to the end, the auxiliary cylinder is fully open. Choose automatic operation, the dry ice production is normal.

Model-SL-650-1 Dry Ice Block Machine

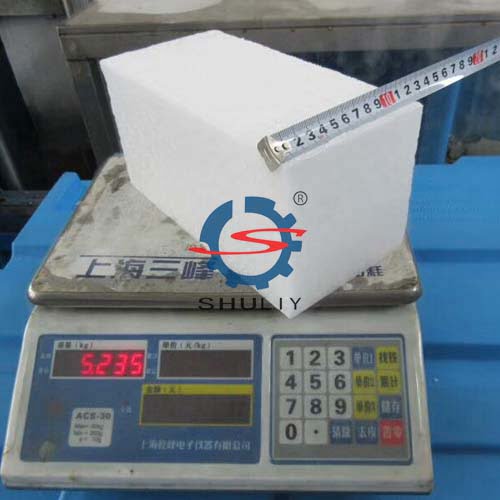

Model-SL-650-1 single-head dry ice block machine can produce the dry ice size is 300*255*(50-260)mm. The minimum dry ice block capacity is about 400kg per hour. The maximum dry ice block capacity is about 650kg per hour. It can produce 3-30kg block of ice. The actual capacity depends on the thickness of the dry ice produced. The thicker the dry ice, the higher the production capacity. The conversion ratio of liquid to dry ice is 2.3~2.5:1. The carbon dioxide water content of the raw material liquid must be <60ppm. Otherwise, the filter barrel of the compression box will be blocked and the dry ice machine will malfunction. At the same time, the extrusion pressure will be increased to cause the oil temperature to rise rapidly and the hydraulic system to malfunction. Liquid inlet pressure needs ≤2.1mpa, otherwise the liquid feed valve will not close properly, causing the dry ice machine to malfunction.

Model-SL-650-2 Dry Ice Block Machine

Model-SL-650-2 double-head dry ice block machine can produce the dry ice size is 300*255*(50-260)mm. Minimum dry ice block capacity is about 800kg per hour. Maximum dry ice block capacity is about 1300kg per hour. It can produce 3-30kg block ice. The actual capacity depends on the thickness of the dry ice produced. The thicker the dry ice, the higher the production capacity. This production capacity of this model is the twice that of the model SL-650-1. The conversion ratio of liquid to dry ice is 2.3~2.5:1. The carbon dioxide water content of the raw material liquid must be <60ppm. Otherwise, the filter barrel of the compression box will be blocked and the dry ice machine will malfunction. At the same time, the extrusion pressure will be increased to cause the oil temperature to rise rapidly and the hydraulic system to malfunction. Liquid inlet pressure needs ≤2.1mpa, otherwise the liquid feed valve will not close properly, causing the dry ice machine to malfunction.

Model-SL-500-1L Dry Ice Block Machine

Model-SL-500-1L single-head dry ice block machine can produce the dry ice size is 250*140*(50-210)mm. Minimum dry ice block capacity is about 300kg per hour. Maximum dry ice block capacity is about 500kg per hour. It can produce 2-12kg block ice. The actual capacity depends on the thickness of the dry ice produced. The thicker the dry ice, the higher the production capacity. The conversion ratio of liquid to dry ice is 2.3~2.5:1. The carbon dioxide water content of the raw material liquid must be <60ppm. Otherwise, the filter barrel of the compression box will be blocked and the dry ice machine will malfunction. At the same time, the extrusion pressure will be increased to cause the oil temperature to rise rapidly and the hydraulic system to malfunction. Liquid inlet pressure needs ≤2.1mpa, otherwise the liquid feed valve will not close properly, causing the dry ice machine to malfunction.

Technical parameters of the Dry ice Machine

| Model | SL-650-1 | SL-650-2 | SL-500-1L | SL-650-1L |

| Motor Power(kw) | 13.5 | 2*13.5 | 11 | 11 |

| Dry Ice Size(mm) | 300*255*(50-260) | 300*255*(50-260) | 250*140*(50-210) | 300*255*(50-260) |

| Dry Ice Min Capacity(kg/h) | 400 | 800 | 300 | 400 |

| Dry Ice Max Capacity(kg/h) | 650 | 1300 | 500 | 650 |

| Dry Ice Density(t/m³) | ≥1.45 | ≥1.45 | 1.3-1.52 | 1.3-1.52 |

| CO₂Transformation rate | 40%-43.5% | 40%-43.5% | 40%-43.5% | 40%-43.5% |

| Liquid inlet pressure(MPa) | ≤2.1 | ≤2.1 | ≤2.1 | ≤2.1 |

| Liquid inlet diameter(mm) | DN20 | 2-DN20 | DN20 | DN20 |

| Exhaust pipe diameter(mm) | DN70 | 2-DN70 | DN70 | DN70 |

| Fuel Volume(L) | 280 | 400 | 320 | 320 |

| Machine Size(cm) | 290*110*190 | 290*160*190 | 250*110*170 | 250*110*170 |

| Weight(kg) | 2800 | 5200 | 2100 | 2600 |