Os pellets de gelo seco são amplamente utilizados tanto na indústria quanto na vida, portanto, o potencial das máquinas de pellets de gelo seco no mercado ainda é enorme. Portanto, neste post, vamos dar uma olhada mais aprofundada em como fazer a produção de pellets de gelo seco, o que procurar no gelo seco e quais máquinas de pellets de gelo seco estão disponíveis para venda em Shuliy.

Etapas da produção de pellets de gelo seco

Com a máquina de pastilhas de gelo seco da Shuli, controlamos rigorosamente a finura e o comprimento das pastilhas de gelo seco ao longo do processo. Siga os passos de trabalho já delineados abaixo para produzir pastilhas de gelo seco que atendam às suas necessidades.

Prepare matérias-primas

A primeira coisa que fazemos neste processo é preparar a matéria-prima (dióxido de carbono líquido) para a produção de pellets de gelo seco. Converta o dióxido de carbono gasoso em forma líquida por compressão e resfriamento. Normalmente usamos uma garrafa Dewar para armazenar o CO2 líquido e, ao usá-la, conectamos diretamente a garrafa Dewar à peletizadora de gelo seco, todo o processo é muito conveniente.

Granulação

Para uma produção de gelo seco mais fácil e rápida, os frascos Dewar são ligados a um granulador de gelo seco. Na câmara de granulação da máquina de gelo seco, o dióxido de carbono líquido é injetado, formando um spray que roda a alta velocidade e, ao mesmo tempo, a temperatura na câmara de granulação é muito baixa para permitir que o dióxido de carbono líquido arrefeça e solidifique rapidamente.

Solidificação e separação

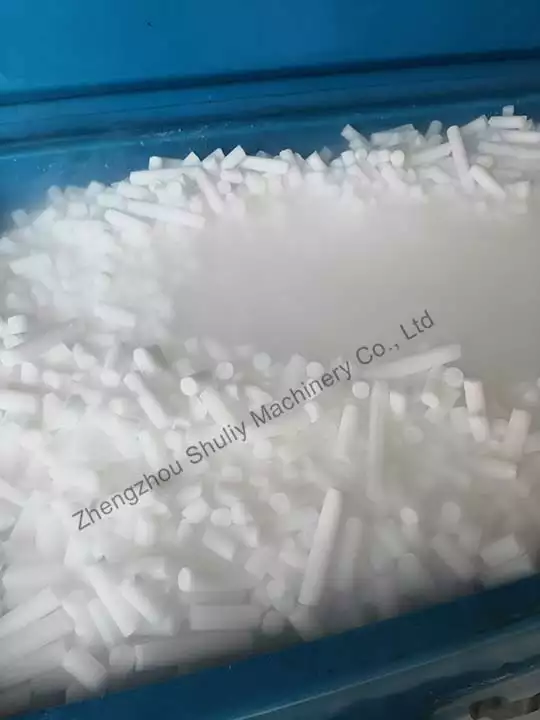

Devido ao efeito combinado da rotação de alta velocidade do spray e da baixa temperatura na câmara de pelotização, o dióxido de carbono líquido é rapidamente solidificado em partículas sólidas de gelo seco, que são então cortadas em partículas de gelo seco do tamanho necessário pelo máquina de corte.

O que deve ser observado durante a produção e uso de pellets de gelo seco?

Durante a produção e utilização de gelo seco, os seguintes pontos devem ser observados:

- Questões de segurança: O gelo seco pertence a substâncias de baixa temperatura, que podem causar danos ao corpo humano e aos equipamentos, por isso é necessário estar atento às questões de segurança na produção e utilização do processo, para evitar causar danos ao pessoal e aos equipamentos.

- Questões ambientais: O processo de produção de gelo seco requer o uso de uma grande quantidade de energia e recursos, por isso é necessário tomar medidas de proteção ambiental para reduzir o impacto no meio ambiente.

- Problemas logísticos: Desde gelo seco é uma substância de baixa temperatura, medidas correspondentes precisam ser tomadas no processo logístico para garantir a qualidade e segurança do gelo seco.

- Problema de armazenamento: Os pellets de gelo seco evaporarão gradualmente à temperatura ambiente, portanto, são necessários métodos especiais de armazenamento para evitar desperdício e perda de gelo seco.

Venda máquina peletizadora de gelo seco Shuliy

Como produtor e fabricante profissional de máquinas de gelo seco, temos vários modelos de máquinas de pellets de gelo seco, a produção é de 50-500 kg por hora e a finura do gelo seco que pode ser produzido é de 3 mm a 19 mm. Além disso, o comprimento dos pellets de gelo seco pode ser definido de acordo com sua necessidade. Também podemos personalizar a máquina especificamente para você, se necessário. Além disso, nossas máquinas são super econômicas e também podem ser customizadas para você de acordo com sua necessidade. Portanto, se você tiver essa necessidade, entre em contato conosco e nosso gerente lhe fornecerá aconselhamento profissional e soluções ideais.