Shuliy dry ice blasting machine uses 1-4mm dry ice pellets as raw materials for deeply cleaning cars, metal casting molds, etc. Our adopts high technology dry ice cleaning method for fast, safe, non-abrasive, and energy-saving cleaning results.

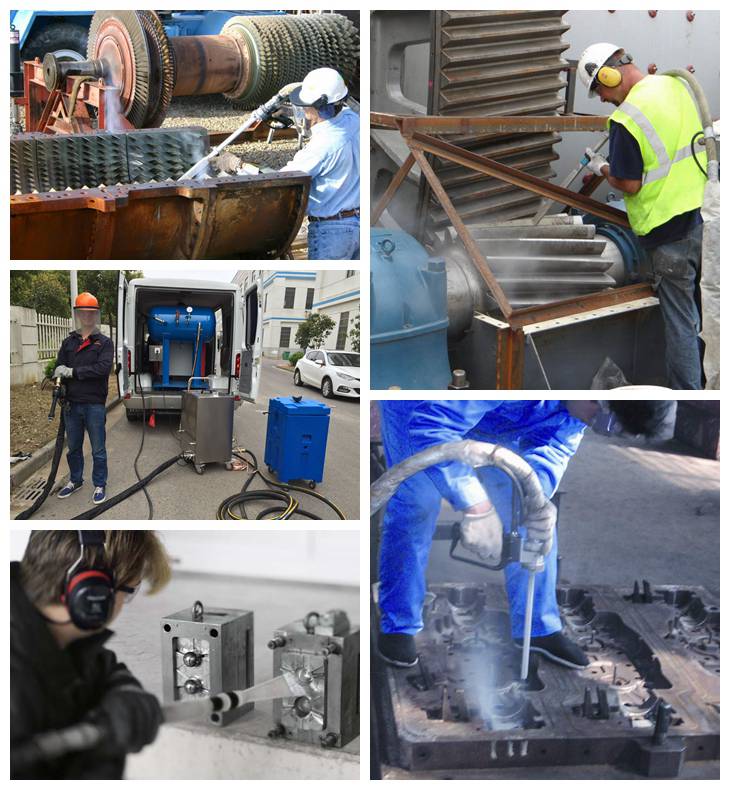

The commercial dry ice blaster machine has a wide cleaning range of applications, such as automobile engines and accessories, metal casting molds, precision equipment and instruments, injection molds, etc.

It’s widely used in the industrial mold industry, petrochemical, food industry, automotive industry, electronics industry, nuclear industry, etc.

Our dry ice cleaning machine can meet your small and medium cleaning business. Interested? If yes, contact us now for more details!

Wide applications of dry ice blasting machine

Our dry ice blaster machine has a variety of cleaning applications, including the following industries.

- Industrial mold

- Tire mold, rubber mold, polyurethane mold, polyethylene mold, PET mold, foam mold, injection mold, etc.

- Petrochemical

- It is mainly used for the main fan, air compressor, hood, steam turbine, and blower cleaning. Also, it’s for cleaning various types of heating furnaces, reactors, etc.

- Printing industry

- Our dry ice cleaning machine can remove various oils, inks, and varnishes. This machine also can clean oil, ink, and dye on gears, guides, and nozzles.

- Food industry

- Food processing equipment, like biscuit oven and conveyor belt cleaning, etc.

- Automotive industry

- Car carburetor cleaning and automotive surface paint removal. Car detailing, tire cleaning, etc.

- Electronics industry

- Cleaning internal grease and dirt of robots and automation equipment.

- General manufacturing

- Blasting oil, paint, ink, adhesive, carbon deposit, asphalt, surface rust, etc.

Advantages of Shuliy dry ice cleaning machine

- It utilizes 1-4mm dry ice pellets as raw materials for various cleaning.

- The machine has a flat or round nozzle, which has a strong jet impact for dirt blasting.

- It applies to a wide range of industries, such as food processing, automotive manufacturing, printing, aerospace, petrochemicals, etc.

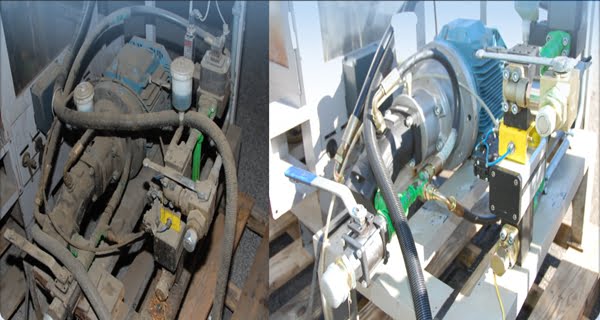

- Compared with traditional cleaning methods, our dry ice blasting machine saves a lot of labor time. The total cleaning time is less than half of the original.

- Our machine is capable of non-destructive cleaning. Dry ice particles will sublimate instantly after impacting the dirt and will not damage the material of the surface to be cleaned. It’s suitable for sensitive surfaces such as precision equipment and molds.

- It has a good cleaning effect in the industrial areas.

- Protect the environment by cleaning with Shuliy dry ice detailing machine. Dry ice cleaning does not use any chemical solvents. Dry ice directly sublimates into gas and does not produce secondary waste.

Technical parameters of dry ice blaster machine

| Model | SL-550 | SL-750 |

| Motor power(kW) | 0.55 | 0.75 |

| Voltage(VAC) | 220 | 220 |

| Air supply pressure range(Mpa) | 0.4-1.0 | 0.4-1.0 |

| Air consumption(m³/min) | 2-4 | 3-6 |

| Dry ice size(mm) | Φ1-Φ3 | Φ1-Φ4 |

| Dry ice consumption(kg/min) | 0.1-2.5 | 0.1-3.5 |

| Hopper capacity(L) | 18 | 28 |

| Air hose length(m) | 9 | 9 |

| Connector screw thread(”) | 3/4” | 1” |

| Ice blaster hose length(m) | 7 | 7 |

| Overall dimension(cm) | 55×40×100 | 58×46×110 |

| Weight(kg) | 110 | 150 |

From the above table, you know that we have two models of dry ice blasters for sale, respectively SL-550 and SL-750. Also, you can know the basic information about dry ice cleaners. If you want to know more machine information, please feel free to contact us and we will provide it for you.

Structure of dry ice blasting machine

Our industrial dry ice cleaner machine is mainly composed of a body, air hose, ice blast hose, nozzle, motor, control button, feeding hopper, etc.

- This machine needs to be equipped with an air compressor. You can use an air hose to connect the air compressor and dry ice blasting machine.

- The length of the air hose is generally 9 meters.

- The air hose uses a rubber tube with a pressure of 8.0 MPa to connect the dry ice detailing machine.

- The dry ice blasting hose is made of imported professional low-temperature resistant rubber pipe. A protective cover is added on the outside.

- Our machine can use a flat nozzle or round nozzle. Generally, we equip the flat nozzle with the machine.

- The flat nozzle is mainly suitable for most working conditions, with a much better cleaning effect.

- The wide flat nozzle cleaning range is wide, which is suitable for large area cleaning.

How does the dry ice cleaning machine work?

Shuliy dry ice blasting machine uses high-speed jetting and physical sublimation principles for cleaning.

- When the low-temperature dry ice particles come into contact with the surface of the dirt, an embrittlement explosion occurs, causing the dirt to shrink and loosen.

- The dry ice particles will evaporate and expand 800 times in an instant. This generates a strong peeling force to quickly and thoroughly remove the dirt on the surface of the object.

What’s the Dry ice blaster price?

The price of a dry ice blasting machine is affected by many factors, such as machine model, machine material, supporting equipment, customized services, packaging and transportation, etc.

If you want to know more details, please read: what’s the dry ice blasting machine price?

Welcome to send us your specific needs to get a quote.

Related dry ice machines from Shuliy

We have been in the dry ice machine business for decades and have a wide variety of dry ice equipment. For example,

We also have other machines that produce dry ice, such as dry ice briquetting machines. If interested, get in touch with us now for more machine details!