Shuliy dry ice cleaning machine is newly designed for cleaning oil stains, tires, automobiles, etc. under high-pressure jetting and physical sublimation. It uses 3mm dry ice pellets as raw materials.

Our dry ice blasting machine has a wide range of uses, strong applicability, and a perfect cleaning effect. Thus, it’s widely used in molds, automobiles, food processing, etc. Interested? If yes, come and contact us now for more!

Highlights of dry ice cleaning machine

- It has a visual cover to monitor the consumption of dry ice pellets in real-time. This keeps the machine running.

- The machine has a high cleaning efficiency. It can clean directly on the equipment without disassembly and shutdown, saving time and efficiency.

- It uses dry ice pellets made of liquid CO2 as raw materials, non-toxic, harmless, non-polluting cleaning.

- It has a wide range of applications, for cleaning precision machinery, automobiles, tires, engines, castings, etc.

- By operating the machine, you can operate it easily and safely.

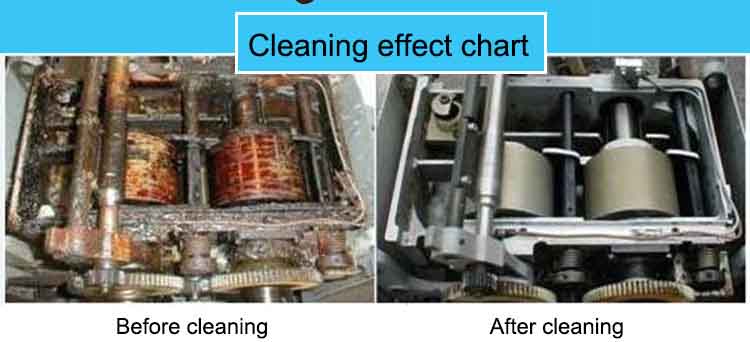

- Our dry ice blaster has a good cleaning effect. Dry ice cleaning does not damage the mold, destroy tolerances, or damage bearings and machinery.

- It has four wheels and is very easy to move around.

- Low inputs and good returns. Our machine is cost-effective, and the raw material(CO2) is easy to use and inexpensive.

- We can customize the machine jetting nozzle, voltage, power, etc.

Technical data of Shuliy dry ice blaster

| Model | SL-40 | SL-80 |

| Dry ice volume | 30kg | 36.4kg |

| Adjustable dry ice dosage | 0-3kg/min | 0-3.2kg/min |

| Air supply pressure range | 5-10bar | 5-10bar |

| Compressed air flow requirement | 2-3m³/min | 2-4m³/min |

| Weight | 65kg | 165kg |

| Dimension(L×W×H) | 60cm×40cm×70cm | / |

| Power supply | 220-240VAC, 1ph(50/60HZ), 3amps | 220-240VAC, 1ph(50/60HZ), 3amps |

From the above table, you can know the machine model, weight, dimensions, etc. When choosing a suitable dry ice cleaning machine, you can refer to this table. If you want more details, please get in touch with us!

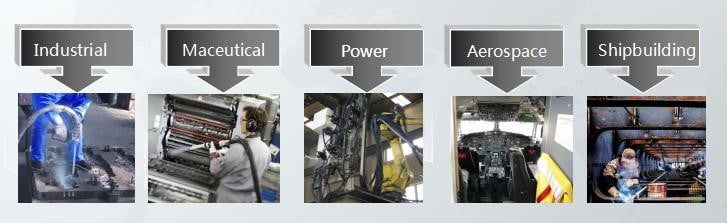

Application and prospect of dry ice blasting machine

Our machine is used in many areas, such as:

- Industrial

- Maceutical

- Power

- Aerospace

- Shipbuilding

- Automobiles

- Car detailing

- Precision instruments

The machine future is bright. Compared to traditional cleaning methods, using a dry ice cleaner is more efficient and cleans more cleanly. With the constant updating of technology and the demand for environmental protection, the dry ice blasting is being used more and more. Our machines will also be used more and more in the world market.

Composition of dry ice cleaning blasting machine

Our machine has a simple structure, ready to understand. It consists of dry ice storage chamber, control panel, jetting nozzle, etc.

Working principle of dry ice cleaner machine

The machine cleans dirt by high-pressure jetting and low-temperature dry ice pellets vaporization.

- When dry ice is mixed with compressed air, it is accelerated in the compressed air. The dry ice granules gradually vaporize.

- Under the acceleration of high-pressure air, the unvaporized dry ice pellets collide with the surface of the object being cleaned. The surface of the object being cleaned is quickly partially frozen by ultra-low temperature in a short time.

- Under the impact of tiny dry ice particles, dirt and other impurities on the object being cleaned are quickly peeled off and blown into the air. Finally, they naturally settled on the ground.

How to correctly use Shuliy dry ice cleaning machine?

To use the machine properly, you should follow the rules.

- Open the cover and add the dry ice pellets.

- Turn on the machine and start dry ice blasting.

- Finish the cleaning work and turn on the machine.

There is a video that describes every step of the correct operation of the machine. You can refer to this video when using it.

What service does the dry ice blasting machine manufacturer provide?

Shuliy Machinery has been a leading manufacturer of dry ice blasting equipment for over 10 years. Our main services include:

- Customized equipment solutions

- Comprehensive pre-sales consulting

- Efficient after-sales service

- Equipment installation and commissioning, technical training and others

- Equipment repair and maintenance

- Technical support and training

- Consumables supply

FAQ

While using the machine, you may encounter a variety of problems. According to our experience, we have summarized, in detail you can refer to: FAQ of dry ice cleaning machine.

If still have any questions about the dry ice blasting machine, welcome to contact us for classification!