Dry ice (solid carbon dioxide or solid CO2) is increasingly popular and widely used with its special physical properties and great benefits. Carbon dioxide becomes a liquid under a certain pressure, and then quickly solidifies to dry ice pellets or blocks under the condition of high pressure and low temperature. Dry ice is applicable in the fields of the cold chain, food preservation, catering, medicine and healthcare, entertainment, industrial deep cleaning, and others. With mature technology, moderate investment cost, and wide application, the dry ice machine (including dry ice granulator machine, dry ice cube making machine, and dry ice blaster) has been greatly attractive to more and more investors.

Why is dry ice becoming so popular?

The popularity of dry ice lies in its outstanding advantages over ice. The dry ice temperature is minus 78.5 ℃. The refrigeration effect of dry ice is more than 1.5 times that of water ice. It absorbs heat and sublimates into carbon dioxide gas, with no residue, non-toxic, and no peculiar smell. Carbon dioxide has the effect of sterilization. When volatilized, it will cause a sharp drop in the surrounding temperature for refrigeration and preservation. Extremely low-temperature dry ice particles, under the action of compressed air, can quickly remove surface impurities of automotive mechanical and electronic equipment after sublimation.

Dry ice-Making machine benefits and market analysis

- Market analysis

Actually, the annual demand for dry ice blaster equipment has increased year by year, and dry ice cleaning service is the inevitable trend of the industrial cleaning industry according to the statistics of various industries, like the automobile industry, electric power industry, petrochemical industry, chemical fiber and textile industry, electronic industry, and others. Meanwhile, in the food industry, transportation industry, pharmaceutical industry, the dry ice products made by dry ice block making machines, and dry ice block pellet making machines are in great demand. Obviously, the market demand for the dry ice machine is huge, and it also shows an increasing trend. This provides huge business opportunities for manufacturers to produce supporting products.

- Economic benefits

It is known that the production of carbon dioxide is convenient and the cost of CO2 collection is not high. The production of dry ice can bring remarkable benefits to industries. In western countries such as Europe, America, and Japan, dry ice is used to replace ice in the food logistics industry to meet the requirements of food preservation due to its superior cold storage capacity and no residue. Traditional ice melts and turns into water, resulting in a sharp decline in the cooling effect. After turning into water, it is easy to produce bacteria. Dry ice can make up for this deficiency. In addition, in commercial transportation, dry ice can replace ordinary ice because it can avoid commodity corruption and reduce transportation costs because dry ice is half the weight of water ice, but its freezing capacity is three times that of water ice. Besides, in the deep cleaning industry, dry ice blasting begins to replace water washing because of fast and deep cleaning effects, no residues, no need for dismantling, and continuous operation.

- Social benefits

Due to the excessive combustion of coal, oil, and natural gas in modern industrial society, these fuels release a large amount of carbon dioxide after combustion. The most important and direct problem is the greenhouse effect, which will lead to many natural and social problems. Through the deep processing of CO2 and the development of its application range, it has created extremely considerable value. The cost of the project is appropriate, which can not only attract production equipment enterprises to actively participate in the development of this environmental protection project but also drive the development of the industry. It is because the raw materials consumed by the products of the project come from “waste products”, there is no polluting gas in the processing process, and energy can be saved, which brings huge economic and social benefits.

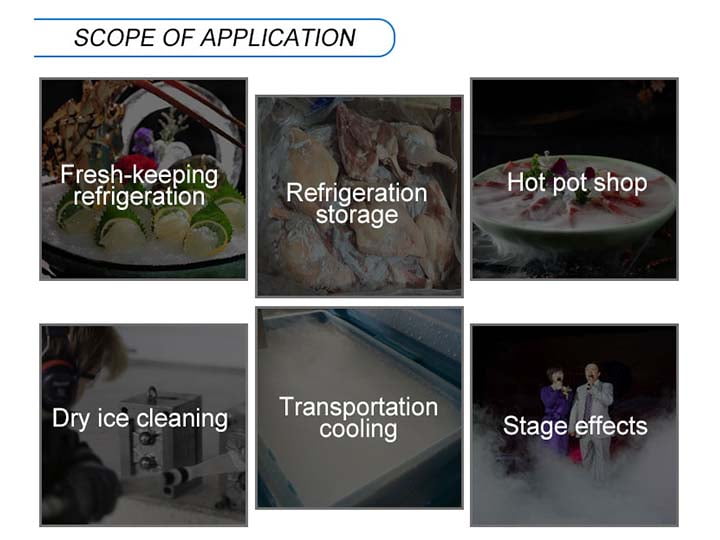

application scope of dry ice manufacturing machine

| Item | Scope of application | Specific application examples |

| Dry ice blasting machine | (1) Electrical Industry (2) Commercial area (3) Industrial area (4) Food industry (5) Other | 1. Deep cleaning of various molding equipment, such as tire molds, plastic molds, metal die-casting molds, and so on 2. Electrical equipment, like motors, printed circuit boards, semiconductors, turbines, control panels, and other precision electronic equipment 3. Automobile interiors cleaning service 4. Heating furnace, welders, piping, printing presses, 5. Roasted food processing equipment |

| Dry ice pellet making machine | (1) Food industry (2) Entertainment equipment (3) Catering industry | 1. Food preservation, like frozen food, seafood, ice creams, wines, etc. 2. Entertainment equipment, like stage smoke, wedding fog 3. Restaurants, pubs, hotels, and ice cream shops, such as making the smoke effect of dishes or beverages in high-ranking restaurants |

| Dry ice block making machine | (1) Cold chain transportation (2) Medical industry (3) Beauty industry | 1. Cold chain transportation of fresh food, seafood, and frozen food 2. Special medicine and vaccine transportation 3. Beauty salons |

Dry ice making machine Types & parameters & Features

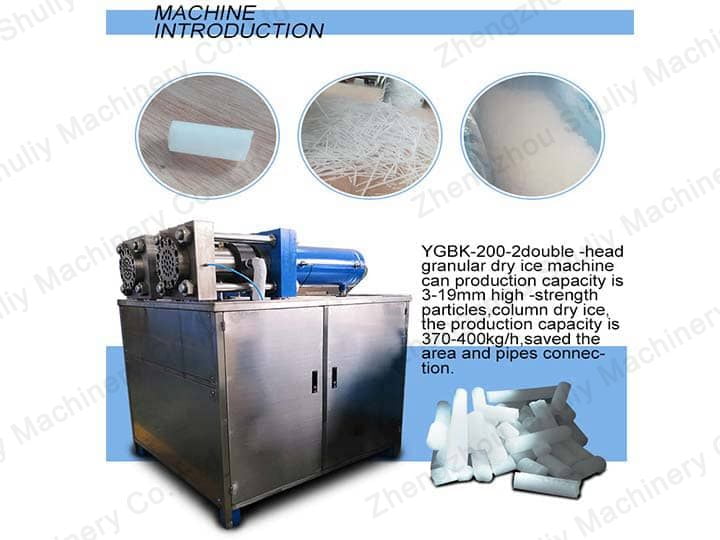

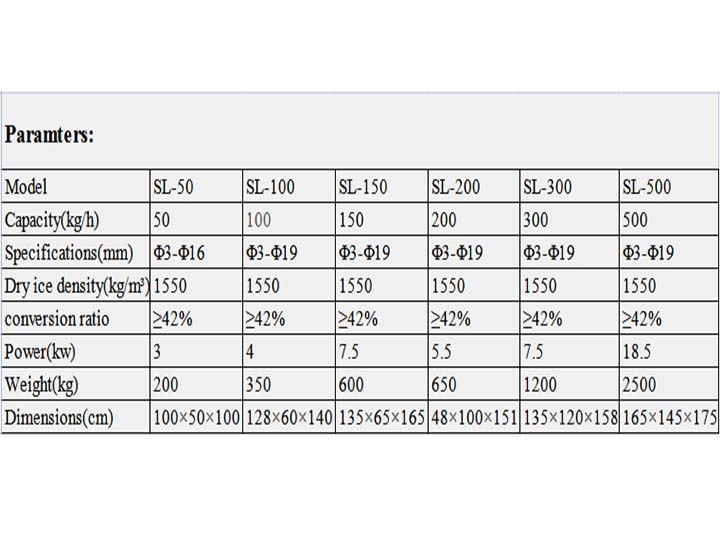

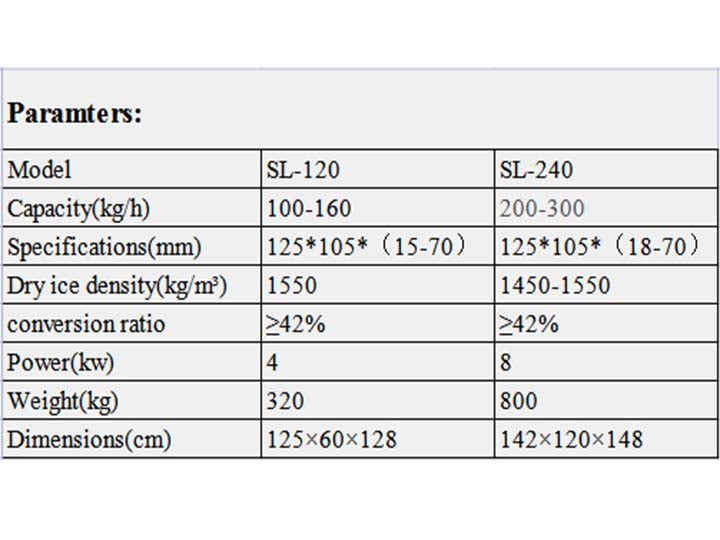

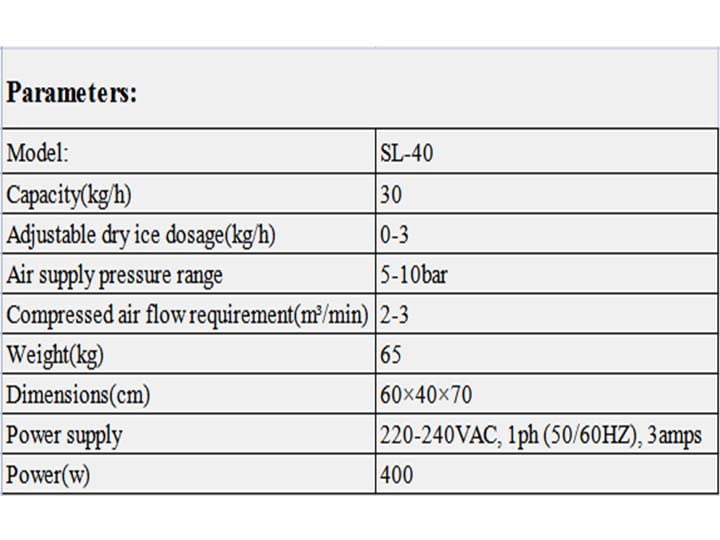

Dry ice pellet making equipment

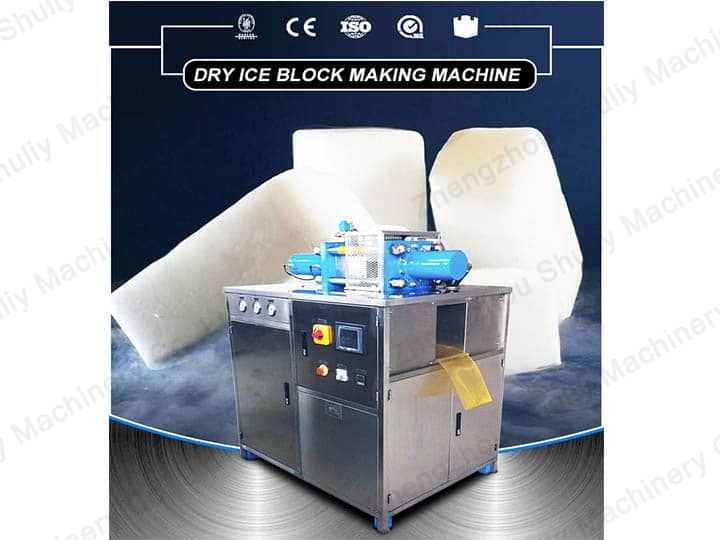

Dry ice block making equipment

The dry ice manufacturing equipment realize automatic and continuous production of dry ice. The expansion of liquid carbon dioxide and the compression of snowflake carbon dioxide are all completed in the compression box. It has the characteristics of high production efficiency, safe and reliable work. In addition, the machine has the characteristics of compact structure and small volume, which reduces the investment and production cost, as well as adjustable sizes of dry ice pellets or dry ice blocks. For special needs, customized services are available.

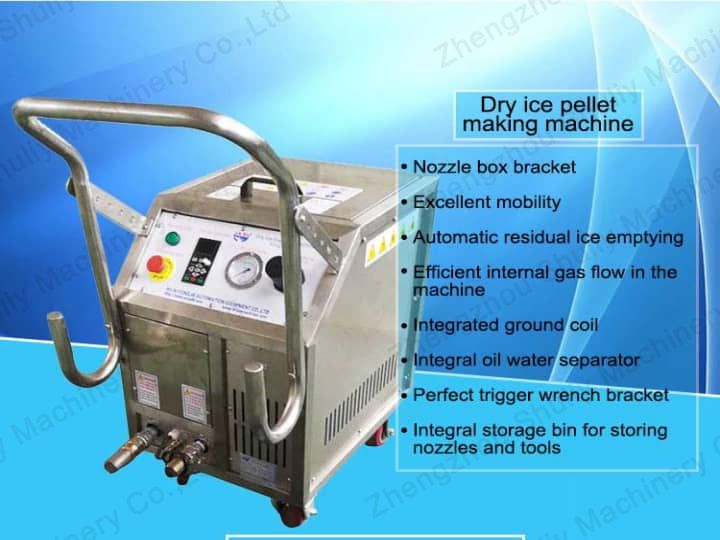

Using dry ice blasters reduces cleaning costs, realize deep cleaning effect and has high productivity without affecting normal production. The cleaning process is relatively dry, and the dry ice can be instantly vaporized with no residue, which will cause no damage to the machine and inhibit the growth of bacteria.

What is the investment cost of a dry ice Machine?

Because of different dry ice making equipment, including dry ice pelletizer equipment, dry ice blaster, as well as various models, the dry ice production equipment price is different. For specific needs, we can offer you a relative quotation for your reference.

In terms of the cost of a dry ice cleaning business, it must integrate the factors of production efficiency. The main consideration is the consumption cost of cleaning raw materials because the dry ice blaster machinery can be reused after one purchase. Cost accounting of dry ice machine needs to be considered from the following aspects: the blasting equipment, raw material cost, cleaning difficulties, product specifications, etc.

As for the cost accounting of the dry ice manufacturing business, the first concern is the price of raw materials. Carbon dioxide as the raw material is the foundation of dry ice manufacturing enterprises. The production cost of carbon dioxide collection is not high. In addition, machine cost, machine configuration, site, labor cost, maintenance cost, etc. need to be considered.

How To Start Dry Ice Business?

First, it is needed to make a clear project plan based on your budget. For example, you need to confirm which specific area to invest in, the plant scale, and the specifications of the final products. The production of dry ice pellets, blocks, or dry ice blasting has different requirements. You can also send your requirement to us for advice.

Second, it requires analyzing the supply and cost of the raw materials of dry ice machine in your local place, as well as the consumption of your expected plant.

Third, it is necessary to choose a suitable dry ice making machines manufacturer, which can offer you advice on your project plan, quality products, and comprehensive services.

Why choose Shuliy Machinery?

Shuliy Machinery is a professional and experienced manufacturer of dry ice equipment for over 10 years. The main equipment includes dry ice block equipment, dry ice granular machine, and dry ice cleaning machine. Our company adopts the latest technology of dry ice machine and constantly follows strict production and management standards. Shuliy dry ice making machines have been exported to a variety of countries and regions, such as the United States, Brazil, Mexico, Peru, the Philippines, Russia, Saudi Arabia, Israel, Singapore, Nigeria, Ghana, Sudan, and South Africa, Sri Lanka, Turkey.

As for products, we have professional R&D teams, technician teams, scientific management, quality control systems, and standardized production. We adopt advanced production technology to ensure the perfect performance of our machinery. The high-quality product has a long service life with stable production. The dry ice machines are time-saving and energy-saving. Regarding customer services, we uphold “Customers’ satisfaction is our ultimate aim” and provide one-stand services for customers. Our considerate after-service brings us positive feedback from global clients.